Wind with a Mind: Smart-Monitoring, Seamless Measuring

Wind Turbine Monitoring Solutions for Power Generation Instrumentation

Transmission Dynamics stands at the forefront of wireless industrial sensor solutions, exemplified by our award-winning engineering expertise in design, development, and deployment of wireless instrumentation.

Turbine Condition & Structural Health Monitoring

Asset Lifetime Extension

Troubleshooting & Turbine Bolting Failures Investigation

Design & Load Validation

The Instrumentation Possibilities are Endless...

At Transmission Dynamics we combine a multitude of engineering disciplines (mechanical, electronics, embedded systems and data analytics) to deliver high-quality, reliable measurements in wind systems.

Your Partner in Optimal Sensor Placement

As the UK lead in the USA-UK Bilateral Collaboration Consortium, we played a central role in the Optimal Sensor Placement for Physics-Based Digital Twins project, driving forward the design and implementation of advanced wireless instrumentation.

The project focussed on identifying optimal sensor placement for digital twinning technology to enable informed and optimised O&M planning and elimination of unnecessary precautionary inspections and interventions for the global offshore wind industry.

Extend the Lifespan of Your Aging Wind Assets with Smart Condition Monitoring

As wind turbines age, the challenge of maintaining reliability and performance grows—but so does the opportunity to extend their operational life. Transmission Dynamics provides advanced wind turbine monitoring solutions designed specifically for lifetime extension (LTE) programs, helping you maximise ROI on aging fleets while minimising unplanned downtime.

Why Monitor Aging Wind Turbines?

Early Fault Detection

Proactively identify wear, misalignment, and structural fatigue before failures occur.

Regulatory & Safety Compliance

Ensure aging turbines meet evolving industry standards with real-time health insights.

Reduce Maintenance Costs

Replace reactive repairs with data-driven interventions, cutting unnecessary inspections.

Optimise Asset Lifespan

Continuous monitoring ensures critical components (gearboxes, bolts, bearings) operate within safe limits, delaying costly replacements.

Effortless Installation, Persistent Monitoring

Our rugged wireless sensors install with minimal turbine modifications, provide decade-long reliability, and enable remote fleet health oversight - eliminating unnecessary and costly site visits.

Key LTE Monitoring Solutions

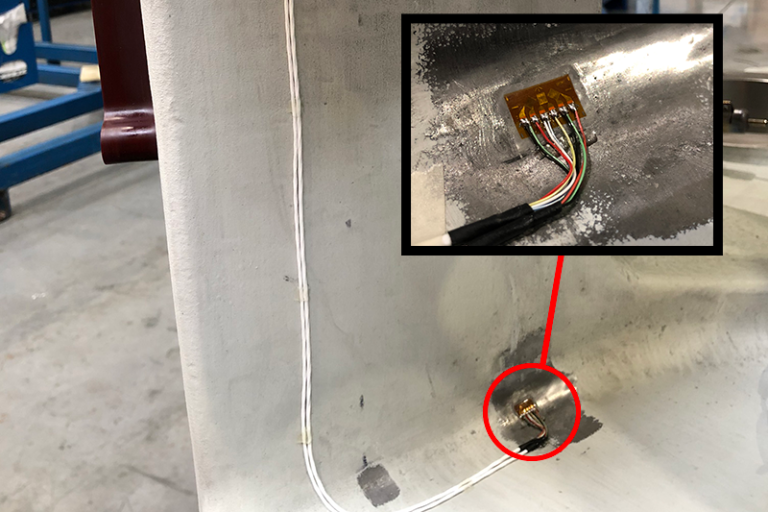

Structural Health Monitoring

Our products detect micro-cracks, stress fractures, and foundation shifts in aging towers and blades.

Gearbox & Bearing Degradation Tracking

Our systems pinpoint early-stage gear wear, preventing catastrophic failures.

Bolt Tension Surveillance

Continuous monitoring prevents loosening in critical bolted joints - a major risk in older turbines.

Load Validation for Retrofits

Verify the impact of upgrades or life-extension modifications with precise strain and vibration data.

The LTE Advantage: Smarter Than "Run-to-Failure"

Many operators of aging turbines face a dilemma: replace or extend? With our wireless sensor networks and physics-based digital twin integration, you gain:

-

Predictive Maintenance

Move beyond calendar-based checks to condition-based strategies.

-

Fleet-Wide Insights

Compare performance trends across turbines to prioritise high-risk assets.

-

Retrofit Readiness

Validate the ROI of component upgrades with before/after performance analytics.

Next Steps for Your LTE Strategy

Whether you’re planning a 10-year life extension or mitigating risks in a 15+ year-old turbine, our bespoke monitoring systems deliver the data you need to decide with confidence.

Consult our experts and let us review your fleet’s LTE potential.

Explore Our Wind Condition Monitoring Solutions

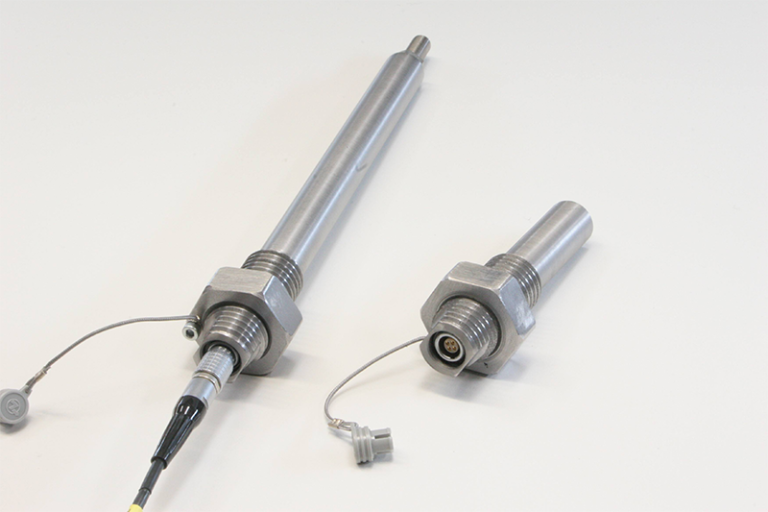

Tower Flange Load Monitoring Fasteners

Blade Stud Load Monitoring

Tower & Jacket Ultrasonic SHM

Tower & Jacket Strain Gauge SHM

Yaw Drive Torque Measurements

Multi-channel Telemetry

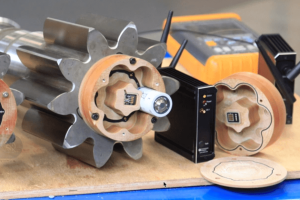

Instrumented Bearing Rollers

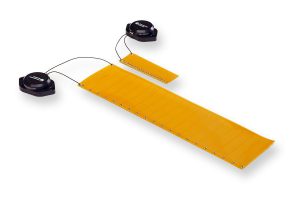

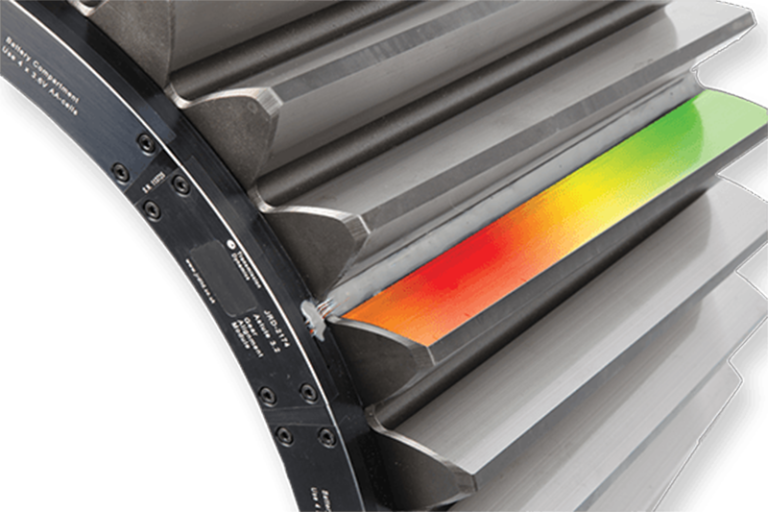

Crack Propagation Measurement

Blade Instrumentation

Bearing Race Slip Measurement

Smart Torque Limiting Couplings

Vibration Measurements

Pressure & Temperature Measurements

Shaft & Roller Alignment Measurements

KillerBug® Torque Measurements

Wind Services

Our team is adept at meticulous gearbox inspections, ensuring longevity and reliability of your turbine operations. Coupled with this, we specialise in noise and vibration measurements, employing state-of-the-art tools to assess and ensure the operational health of your wind assets. Additionally, our expertise extends to failure mode analysis, allowing us to pin-point the root of problems; enabling maximisation of uptime and efficiency of wind turbine monitoring.

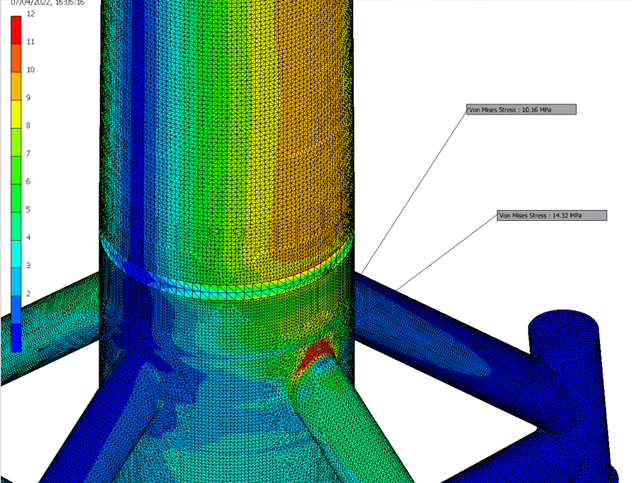

Finite Element Analysis

Some of our Wind Generation Clients

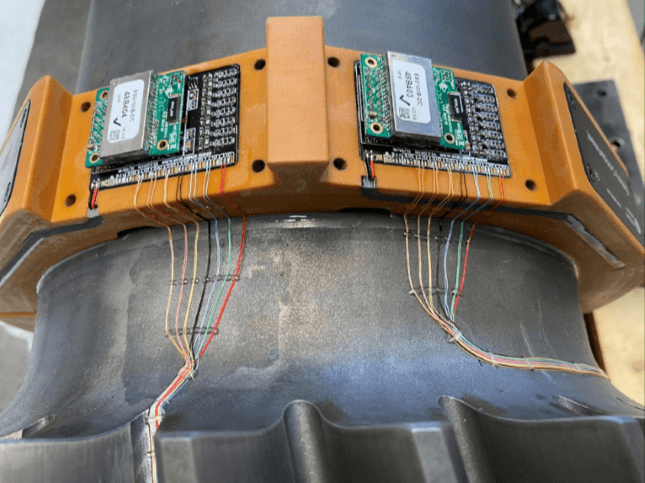

Gearbox Instrumentation

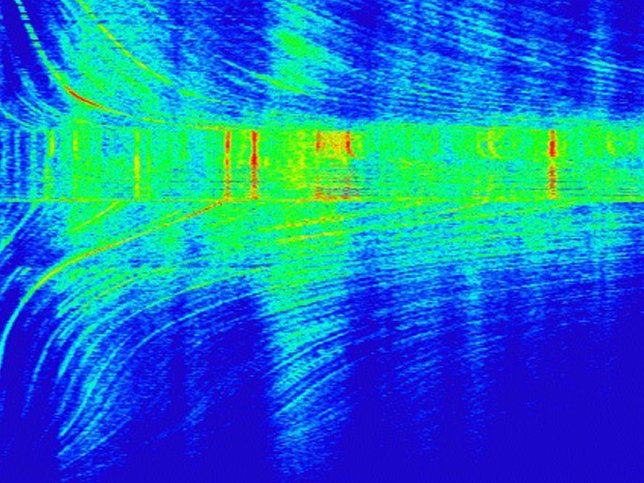

Gear Load Distribution Measurements

Plain Bearing Oil Thickness & Pressure

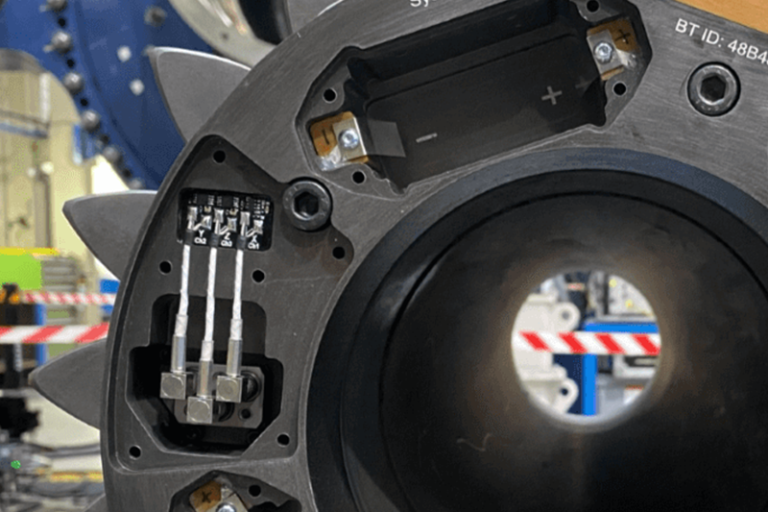

Bolt & Fastener Instrumentation

Torque & Bending Measurements

Temperature Telemetry

Stress Measurements (Strain Gauging)

ODS Measurements

Shear Pin Measurements

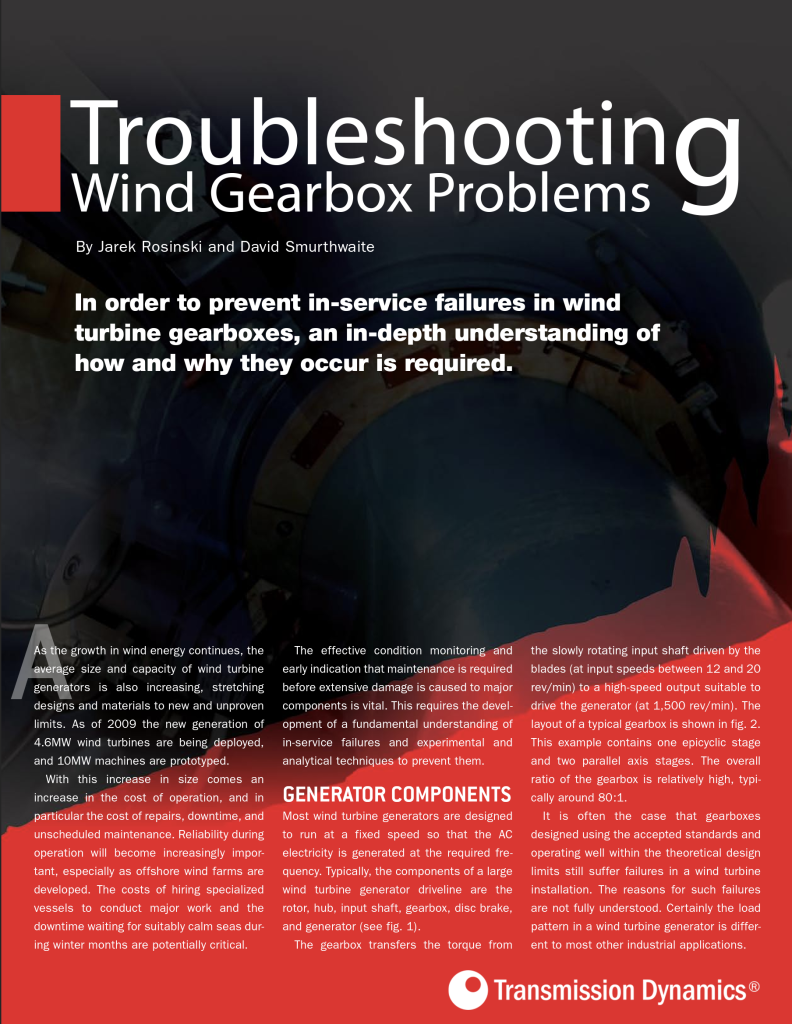

Tackling Wind Turbine Gearbox Challenges: A Comprehensive Analysis

Transmission Dynamics CEO Jarek Rosinski along with David Smurthwaite delve into the complexities of preventing in-service failures in wind turbine gearboxes. As wind energy continues to surge, larger turbines pose new operational challenges, driving up costs and maintenance needs.

With a focus on gearbox dynamics, the authors explore critical factors influencing reliability and propose advanced monitoring techniques for enhanced performance and longevity.

Through meticulous examination of real-world data, they highlight the importance of proactive maintenance strategies and collaborative industry efforts in ensuring the sustainability of wind power generation.

Please click the image to view a PDF of the article, which opens in a new window/tab.

Understanding the importance of Bolt Tension in Wind Turbine Integrity

- Engineering projects worldwide rely on critical bolting applications for safety and efficiency.

- Bolt failures are a major challenge, particularly in the wind energy sector.

- Accurate and continuous data of bolt tensions is crucial to prevent incidents.

- Hydraulic tensioners used in wind turbines have a fundamental problem with achieving correct bolt tensions.

- Many wind turbine bolts are not installed to specified preload, causing potential safety risks.

- Bolt tensions are typically checked only every 6 months, leading to potential loosening in between.

- Transmission Dynamics Technology offers live wind turbine monitoring for immediate and effective addressing of turbine bolting failures.

Unleash the power of cutting-edge solutions from Transmission Dynamics.

Discover Transmission Dynamics’ cutting-edge technologies tailored to elevate your operations. From wind turbine monitoring systems to wireless telemetry solutions, we deliver unparalleled performance, reliability, and cost-effectiveness. Our expertise in providing real-time data insights and power generation instrumentation empowers your business to make informed decisions and optimise performance.